Ingot Production

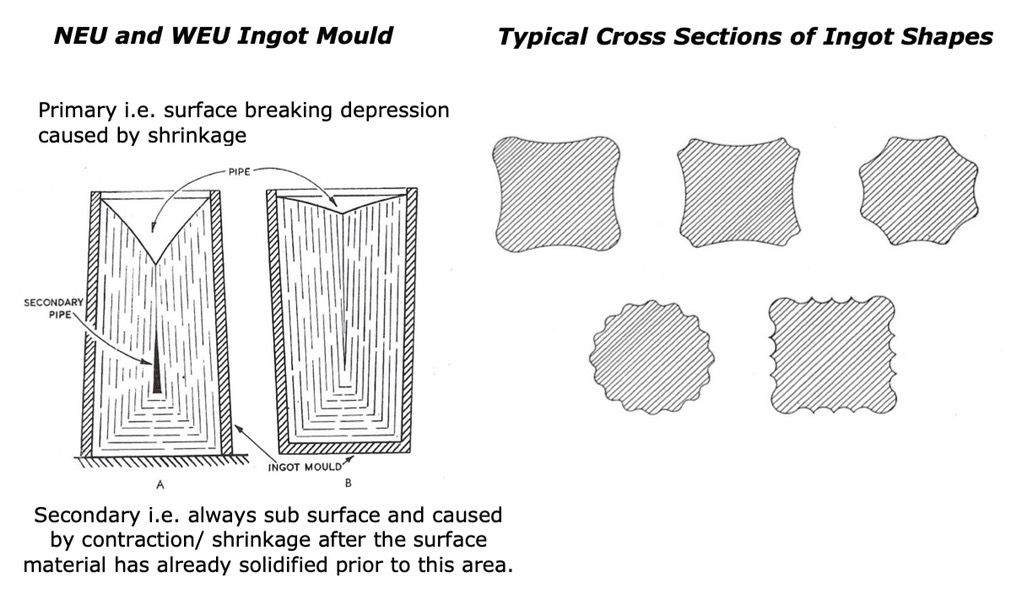

The molten metal from the steel making process is teemed* into moulds to solidify. Ingot moulds can be separated into 2 basic types, Wide End Up (WEU) and Narrow End Up (NEU) and in cross section are usually shaped to avoid sharp corners which could lead to cracking.

Teeming is the steel 50 industries term for the pouring of a molten metal.

Before teeming, additions are made to the metal to add alloying elements or to remove gases in solution (molten metal will dissolve gases forming iron oxide) the amount they will dissolve becoming less as the temperature falls so the gases come out of solution and form bubbles. Gases evolved are normally CO (Carbon Monoxide) due to carbon/ oxygen reactions which re- form as CO2 (Carbon Dioxide)

Formation of these gases may be suppressed by adding de-oxidation materials such as ferromanganese, aluminium, silicon.

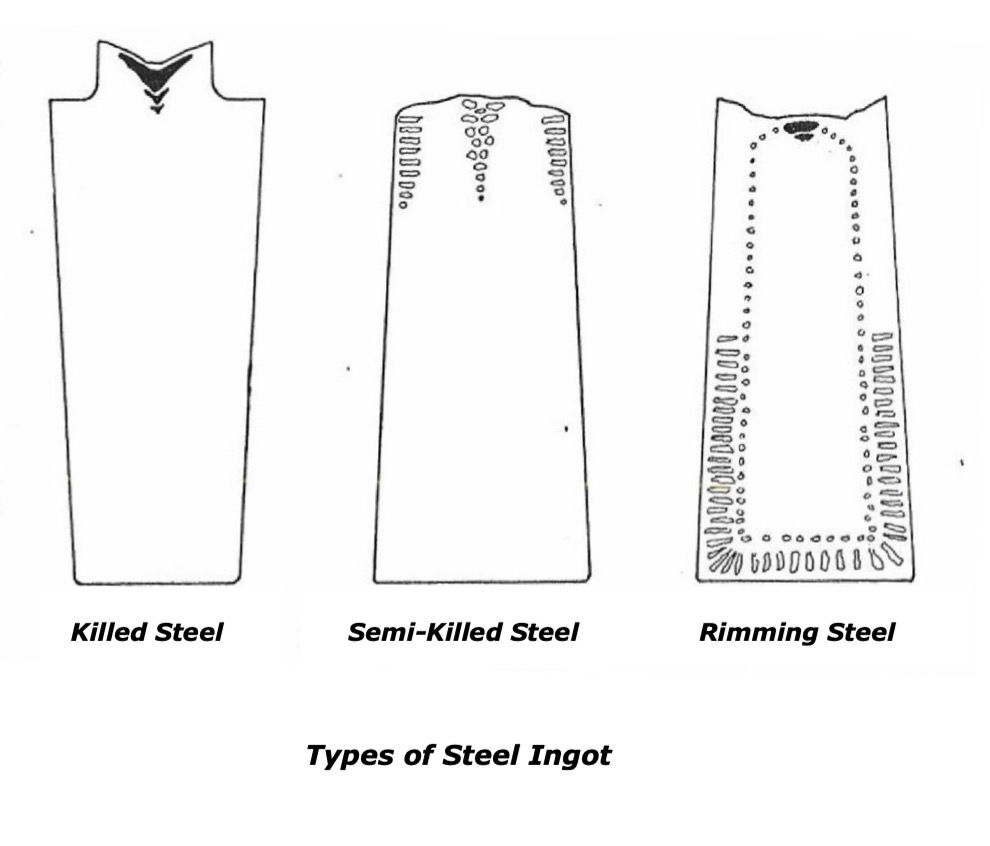

Rimming steel ingots

These ingots are produced by semi-killing the steel in the ladle with silicon (Si), just sufficient to allow oxygen to react with the carbon in the rim of the ingot producing blowholes of CO2 and a pure iron rim free from carbon. The subsurface CO2 gas blowholes welds up on rolling.

This is mainly used for sheet, although used in plate form for non-critical applications.

Killed steel ingots

These ingots are produced by fully killing the steel prior to transfer of the liquid steel from ladle to ingot mould. All carbon/oxygen reactions are killed by either silicon or aluminium, or a combination of both. Aluminium also refines the grain structure producing fine grained steels.

Semi killed ingots have a reduced level of additions to allow for some reactions.

All engineering grades of steel, high alloy and tool steels are killed steels.